Mobile Diagnostic Lab, Iowa State University

– In collaboration with Ulrike Passe and CBER.

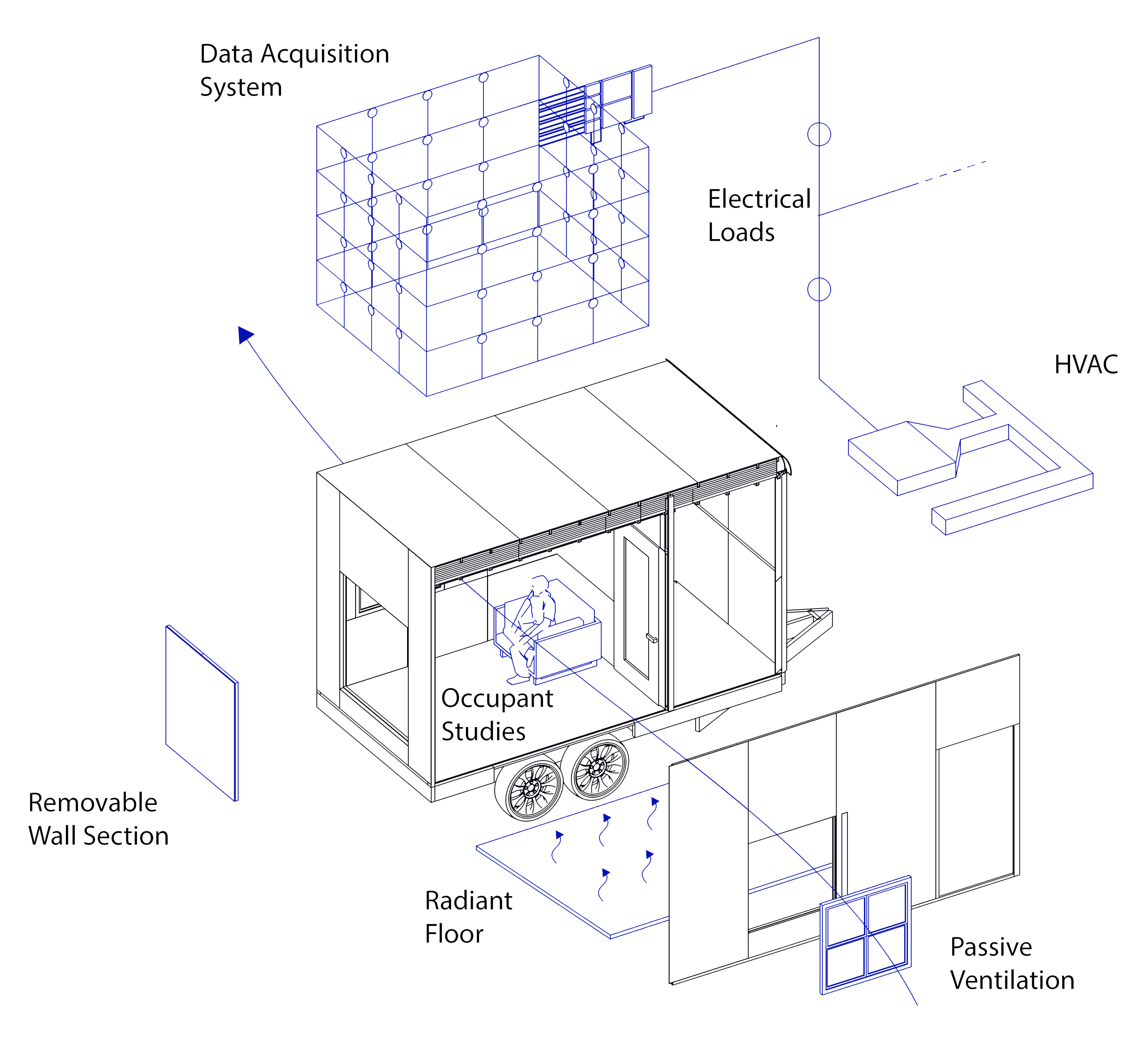

The mobile research and diagnostics lab (MDL), is a mobile structure designed and constructed by an interdisciplinary team of researchers at the Center for Building Energy Research (CBER) at Iowa State University. The lab is designed to be flexible, so it can be moved to various locations collecting performance data. The trailer is embedded with a suite of thermistors and humidity sensors within the wall assembly.

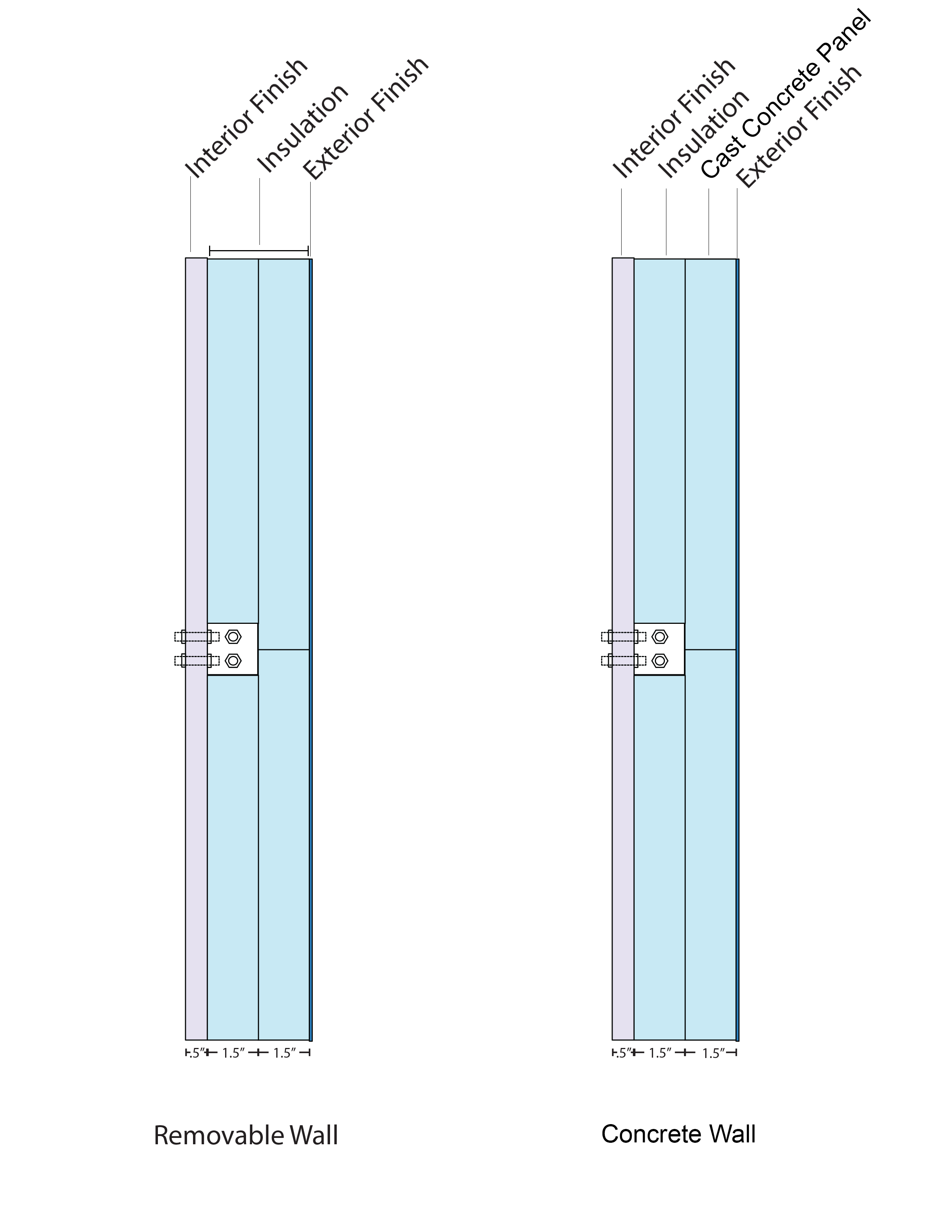

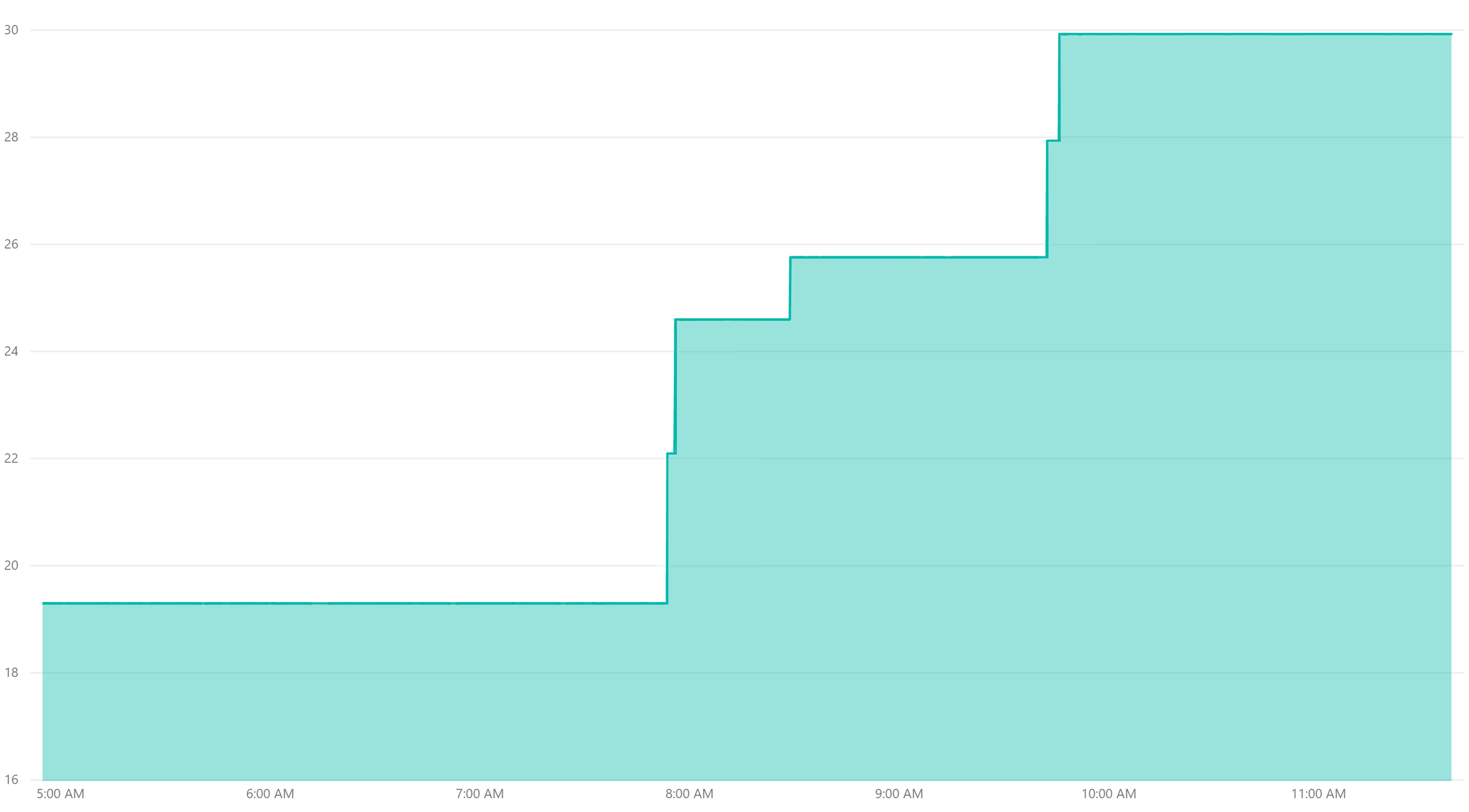

The trailer can be towed to various locations collecting temperature and humidity data to create site specific micro-climate studies that can better inform building design. Temperature and humidity sensors are evenly distributed through the wall gradient, with one thermistor per layer. This enables the collection of multiple data points specific to the material assembly as heat flows through the assembly. The assembly consists of two layers of insulation, one polystyrene, the second a foam faced insulation, wood framing, interior poly-carbonate sheathing that can be removed for easy access to the wall assembly, and an exterior metal sheathing that protects the entire assembly.

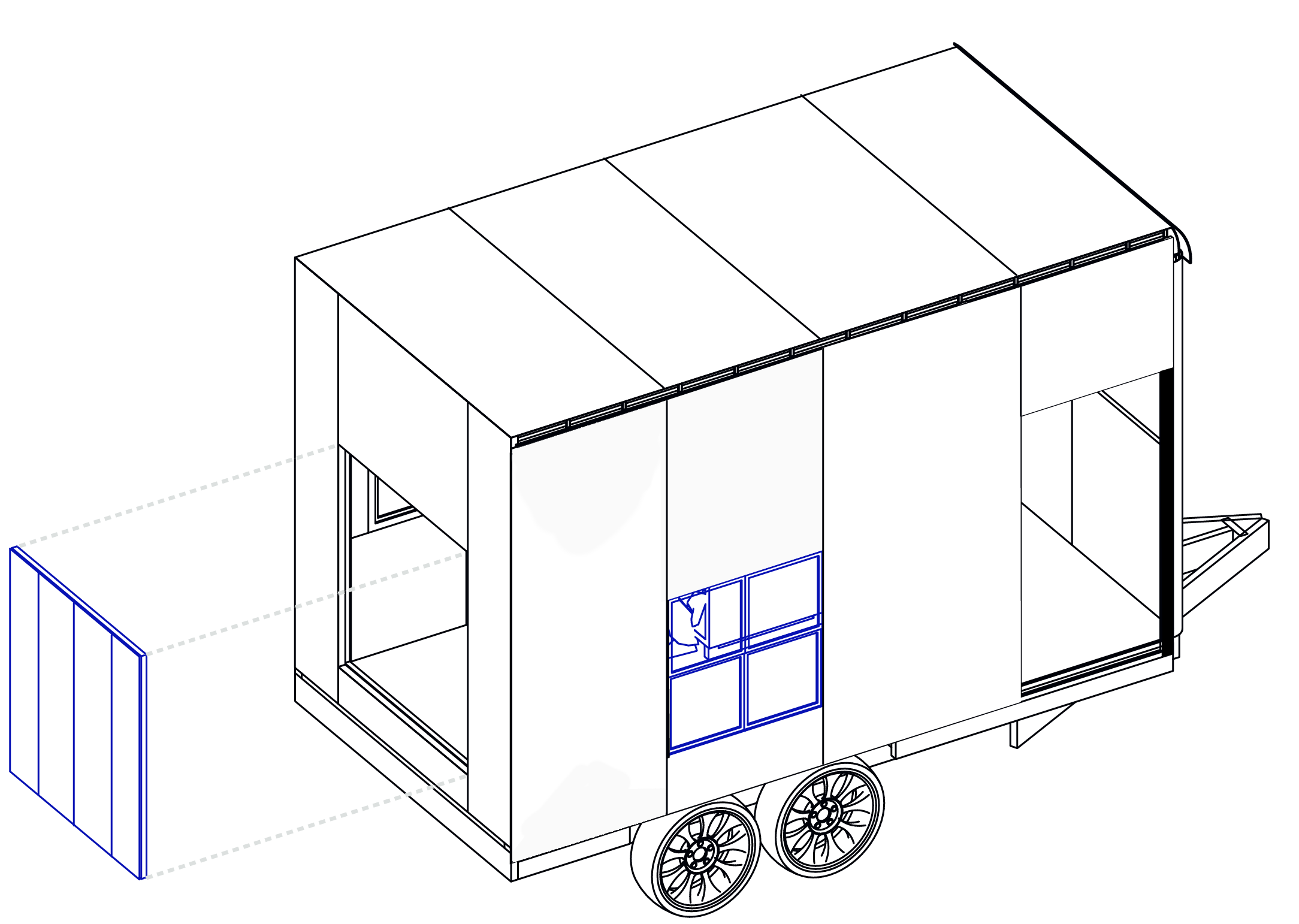

The trailer is split into two sections, the data collection and HVAC space, and the measurement space where experiments such as, heat flow through the thermal assembly, passive ventilation, comfort analysis, material analysis can be conducted. The MDL has removable interior wall panels allowing access to the wall assembly, insulation, and thermistors.

Additionally, the rear wall of the trailer has a segment that can be removed and replaced with a custom wall assembly. This allows for testing of different material assemblies within the conditioned space, comparing assembly performance to established high performance assemblies.The custom assemblies can be tested for water resistance, humidity resistance, and thermal gradient through the custom assembly. The assembly can also be used to test changes in energy consumption with micro-climatic variation.