Fiber Reinforced Concrete Shells, Iowa State University

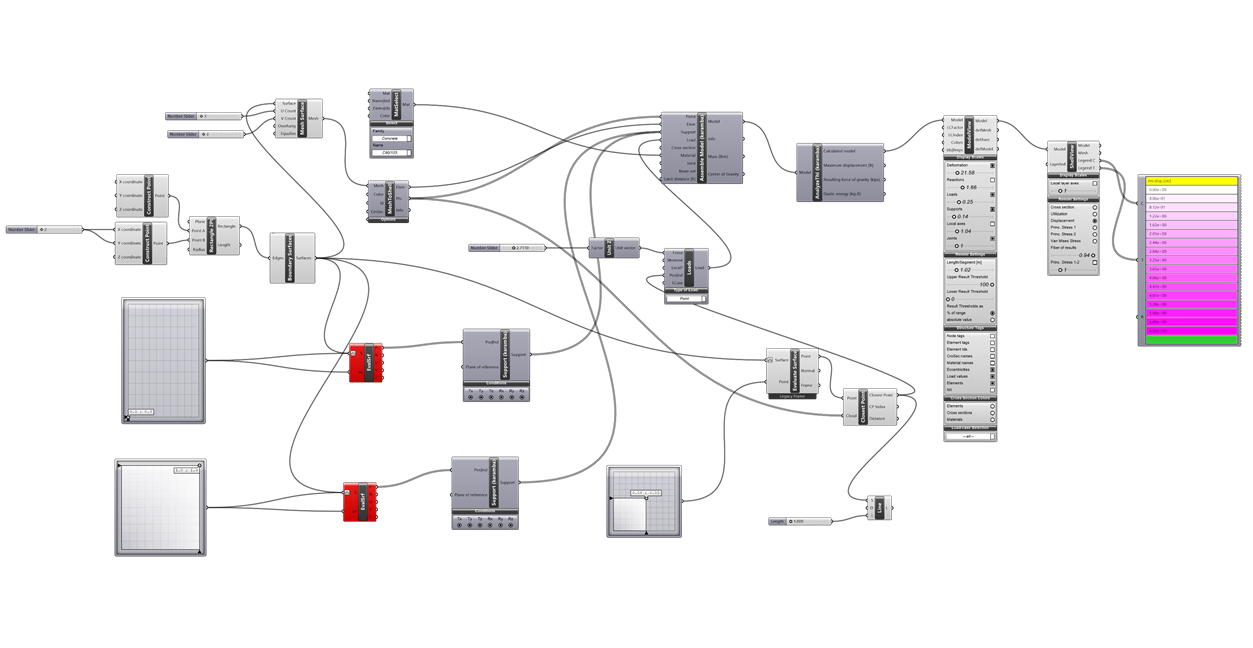

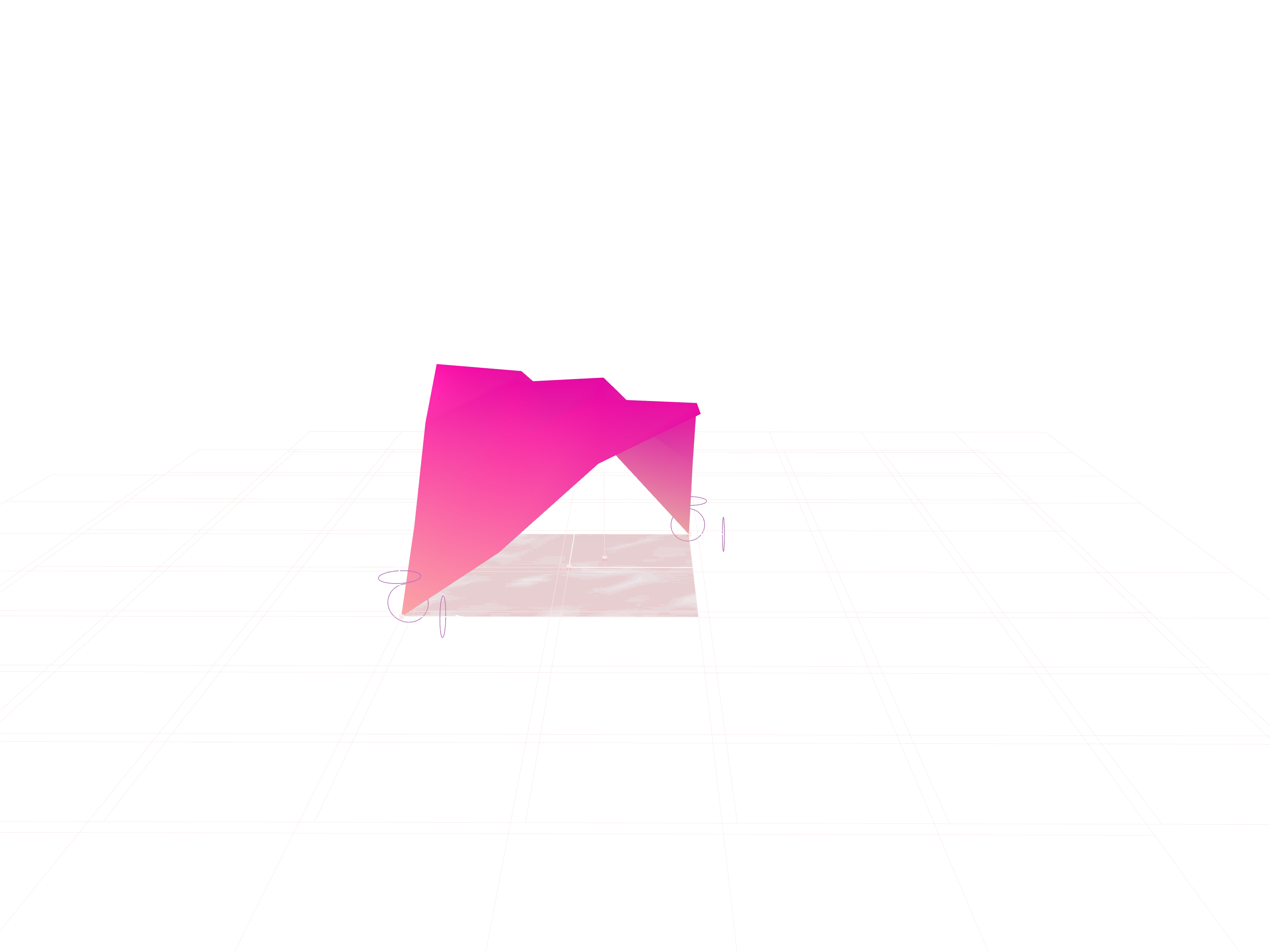

Workflow: Rhino/Grasshopper/Karamba, Laser Printer.

The aim of this investigation was to create scale concrete shells as a means of testing cellulose-based applications utilizing cellulose nanocrystals. This study would be the primary step for testing cellulose-based applications with region specific fibers. This would provide alternatives to the spatial conditions that define the standardized wall assembly. Additionally, this would provide a framework for incorporating region specific fibers reducing reliance on contemporary modes of construction that contribute to higher energy consumption and community-based equity.

The CNC is chemically modified product where the cellulose fibers are aligned in single direction when dispersed in water, imparting higher mechanical properties (CelluForce 2016). The spindle shape of the fibers allow them to form liquid crystals in a fluid medium. Concentration of the fluid results in the spindles self-orienting and forming layers where each layer is oriented in the same direction. The high crystallinity imparts the CNC with its high strength. Each crystal has a stiffness of 150 GPa and a tensile strength in the order of 10 GPA.

Concrete shells are designed through form finding methods where an optimum form, which can resist the various loads through its curvature in both directions, is generated. The concrete matrix resists compressive loads through membrane action to the supports with reinforcement to tackle tensile forces that develop in the shell.A well-formed concrete shell has almost no bending apart from membrane stresses, axial compression and tension, allowing a thickness of 80mm for reinforced or prestressed concrete.

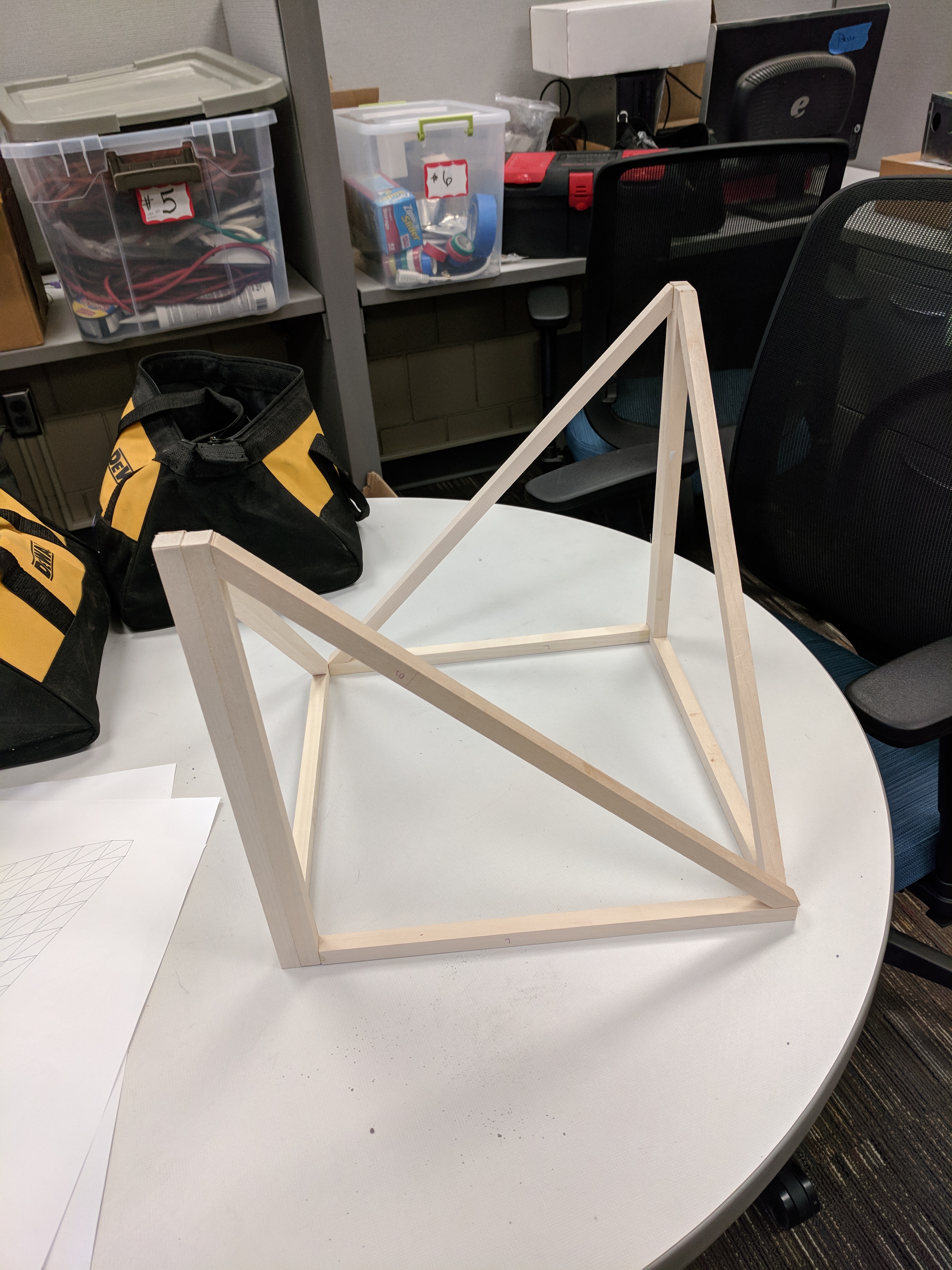

Therefore, the objectives of this study were to create scale concrete shells by mixing the cellulose nanocrystals (CNC) with concrete investigating application strategies through digital design and physical mock-ups. Sample test cylinders were created to test and study the role of CNC in improving its mechanical properties. The structural strength demonstrated through the addition of cellulose nanocrystals is currently attributed to close packing of the crystals allowing for reduced inter-fiber spacing in the cement matrix. This leads to greater interaction between the cellulose and the cement system during the curing process, thereby demonstrating greater potential to alter micro-cracking leading to increased overall strength.

The thin shells could be utilized in humanitarian crises areas or in rural communities instead of a contemporary assembly which relies on standard materials. The shells could be set up rapidly with a modular formwork. The reusability of the formwork combined with region specific fibers to create the shells can help in the construction of a greater number of thin shell concrete structures in comparison to traditional thin shell concrete structures.